Cut Rebar Optimization

Inefficient rebar cutting patterns lead to significant material waste and increased project costs. Maximize your material efficiency with our professional Cut Rebar Optimization Tool and dramatically reduce waste while improving your project profitability and resource utilization.

How This Tool Helps Your Steel Business

Optimize cutting patterns to minimize rebar waste and maximize material usage

Reduce project costs through intelligent material planning and cutting strategies

Improve project efficiency with automated cutting pattern calculations

Eliminates manual guess work and saves employee time

Key Features

Our tool provides everything you need to optimize your rebar cutting

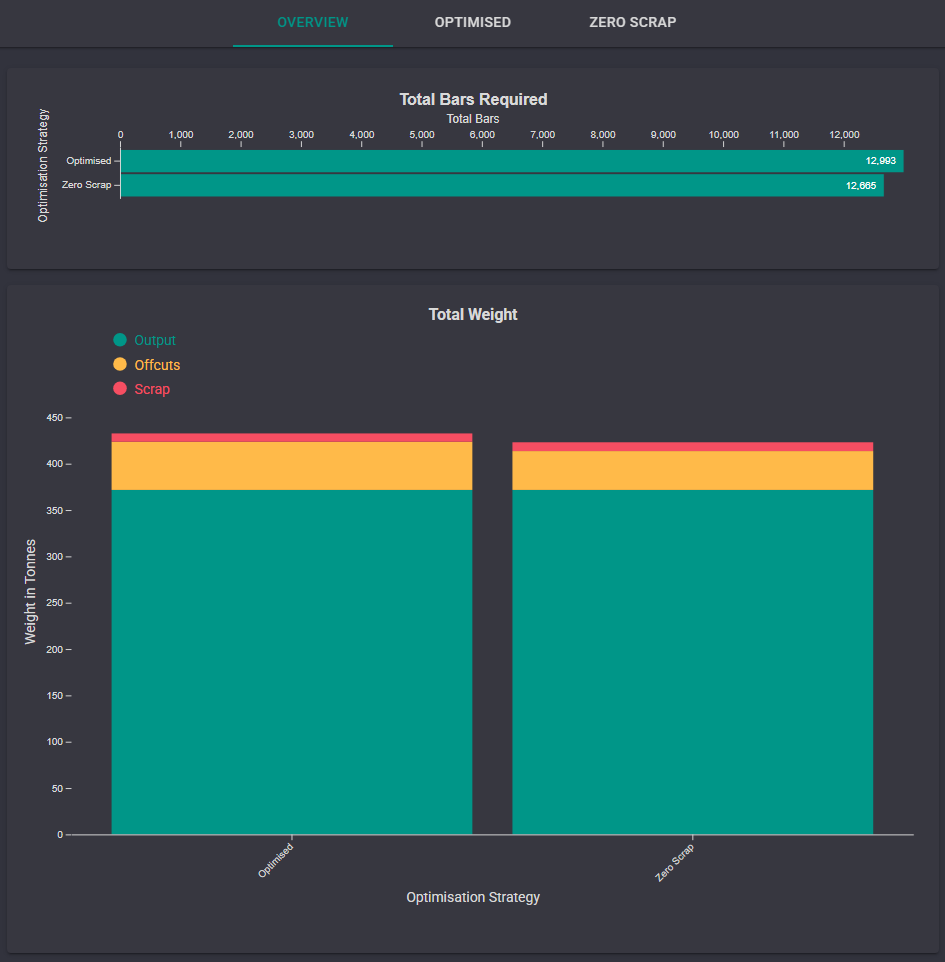

Cutting Pattern Optimization

Generate intelligent cutting patterns that minimize waste and maximize material efficiency for your rebar requirements

Material Efficiency Analysis

Calculate optimal bar lengths and cutting sequences to reduce offcuts and improve overall project material usage

Automated Processing

Run complex optimizations overnight with results ready for your morning planning sessions, eliminating manual calculations

Time-Saving Automation

Eliminate guesswork and manual planning - our algorithms handle complex cutting calculations, freeing up your team for other critical tasks

How It Works

Sync Inventory Data

Upload or sync your current rebar stock inventory including available bar lengths and quantities

Upload Order Requirements

Input your project orders with required rebar lengths, quantities, and specifications

Run Optimization

Hit run and our algorithms will process your data to generate the most efficient cutting patterns and material allocation